Commercial Space

Flux has supplied custom-made inductive components, inductors, and transformers, to the traditional space industry since 1995, building on the heritage of the Alcatel Space principles that were founded in 1973.

Commercial Space or New Space are both headlines describing a general disruptive trend in innovation and commercialization of the space industry. The industry was initiated by new commercial actors, paving the way for industrialization, private investment, and digitalization.

Commercial vs. Traditional Space

Commercial Space can be regarded as an add-on to the existing traditional space industry as the service offerings of the two sectors are largely complementary.

Commercial Mega constellations, flying in Low Earth Orbit, focus on digitalization whereas the traditional space industry typically supplies heavier space vehicles flying in Geo Stationary Orbit for Earth observations and science or deep space missions with a significantly longer lifetime.

The implications of quantity, mission lifetime, and financial aspects have fostered innovative approaches in the supply chain of these highly differentiated industries.

Qualified Manufacturer

In the early days of Commercial Space (early 2000s), Flux recognized the potential of a new ecosystem and engaged in developing practices. A standardized practice was needed for design, material choice, and processes to provide larger quantities of components, matching the technological and financial requirements of this emerging industry.

Flux is a Technology Flow Qualified Manufacturer - one of only six such approved companies and the only one qualified by ESA for manufacturing custom magnetic components following ESCC3201/013 – the quality standard for electromagnetic components defined by Flux and adopted by ESA.

On the path for our current commercial space concept since 1995

Additional commercial space activities

Do you wish to know more about our involvement in the industry?

Hover over the cards below!

OneWeb

Flux delivered 10.000 components to OneWebs satellite constellation

Micross, a trusted supplier of space-grade DC/DC converters, needed to partner with trusted suppliers of cost-driving components to develop and produce 2,000 isolated DC/DC converters for OneWeb.

Components that Flux was asked to manufacture, test, and screen to ensure that they were of the highest possible standard.

The Magnetorquer Rod

Space Inventor, a satellite manufacturer, and Flux recognized the industry’s demand for the magnetorquer rod.

Flux was asked to participate in developing the highly reliable magnetorquer rod, aiming to deliver superior performance, reliability, and integration efficiency.

A joint partnership

The collaboration between Space Inventor and Flux had several advantages; including enhanced performance, reliability, integration- and energy efficiency.

Want to know more? Read the entire story by clicking here

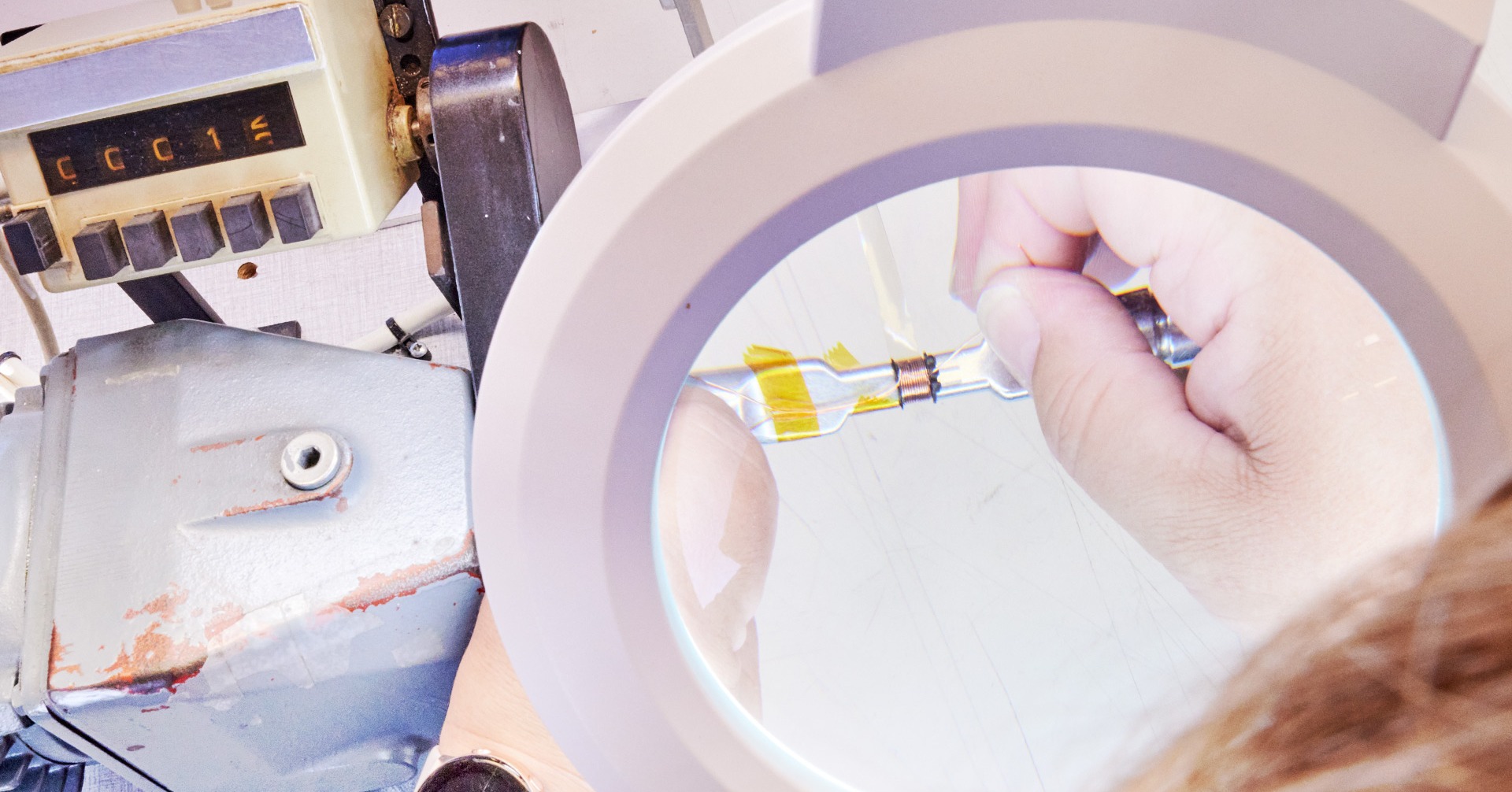

Understanding the concept of quality

As a traditional supplier of space components, it has always been Flux’s philosophy to supply high-quality, flawless, and enduring space components. We always implement the following elements in our manufacturing setup:

-

Electrical and mechanical design

-

Choice of material

-

Procurement and production processes

-

Inspection criteria

-

Electrical and environmental testing requirements

-

Quality management

-

Education and training

-

Additional commercial activities

Defining the concept of Commercial Space

Flux has conceptualized and designed a standardized practice for design, material choice, and processes to enable the production of larger quantities of components that match the technological and financial requirements of the industry.

By combining the above-mentioned capabilities and maintaining full traceability, we can offer AS9102 First Article Inspection and the option of full Space Grade Screening on our space products.

Flux further offers the production of bespoke designs originating from the buying entity.

Extensive experience in the optimization of power-magnetic components

At our headquarters in Asnaes, Denmark, teams of dedicated engineers are ready to work closely with our customers in designing power magnetics for your projects.

You can approach us with a finished topology or a series of requirements for your upcoming power solution project and trust our expertise when it comes to the design process or optimizing materials, production design, or product layouts.

Our engineering department has extensive experience in the optimization of power magnetic components – not just when it comes to the topology and the design-for-manufacturing aspects of the components, but especially in terms of the materials used.

Want to know what Flux can do for you?

Get in touch with Lars Gregersen - COO of Defence and Space.

Other markets we serve:

Renewable Energy

We deliver custom-made magnetics solutions for wind, solar, and wave power.

Industry

We develop, design, and manufacture custom-made and standard-range magnetic components for all types of industrial applications.

Automotive

We create and deliver components to the ever changing industry of electrical charging.

Defence and Space

We develop and manufacture high-reliability magnetic components for aerospace applications.